Essential Guide to Choosing the Best Timing Belt Pulley for Efficiency

When it comes to performance in power transmission systems the pulley is key. Whether you’re designing a robotic arm, building industrial machinery or working on medical devices the right pulley will give you high efficiency, precision and longevity. In this guide we’ll show you how to choose the best pulley for performance.

What are Timing Belt Pulleys

Timing belt pulleys are the backbone of power transmission applications, a reliable and efficient way to transfer rotational motion. These pulleys can come with single or double flanges to suit different application needs. In essence, timing belt pulleys are toothed wheels that work in conjunction with a timing belt—a toothed belt that transmits power between two or more shafts. These pulleys are usually made from durable materials like aluminum or steel to withstand the high-speed stresses and strains they are subjected to.

One of the biggest advantages of timing belt pulleys is the range of sizes and configurations available. Whether you’re working on a small hobby project or a complex industrial machine, there’s a timing belt pulley for you. They are especially crucial in synchronous drives where timing and synchronization are key. In these setups, the timing belt pulley ensures power is transmitted between shafts while maintaining the exact timing relationship required for the system to work efficiently and perform.

Once you understand the role and construction of timing belt pulleys, you can appreciate their importance in a smooth, efficient, and reliable power transmission system.

Why Pulley Matters for Efficiency

Timing belt pulleys convert rotational motion with accuracy. The toothed design allows for slip-free transfer, and our selection of timing belt pulleys ensures synchronized movement between parts. Choosing the right pulley is key to maximizing efficiency, reducing energy loss and extending the life of your system.

We offer custom manufacturing for timing belt pulleys where we can design and manufacture components to specific application requirements. These pulleys are complete solutions that require no additional work from the customer to integrate into their application. Using aluminum pulleys for example reduces system weight and inertia which in turn increases efficiency. Let’s dive deeper into how to choose the best.

Timing Belt Pulley Types

We offer various timing belt pulleys to meet design and performance requirements. Below are the types available, each for different applications and compatibility:

|

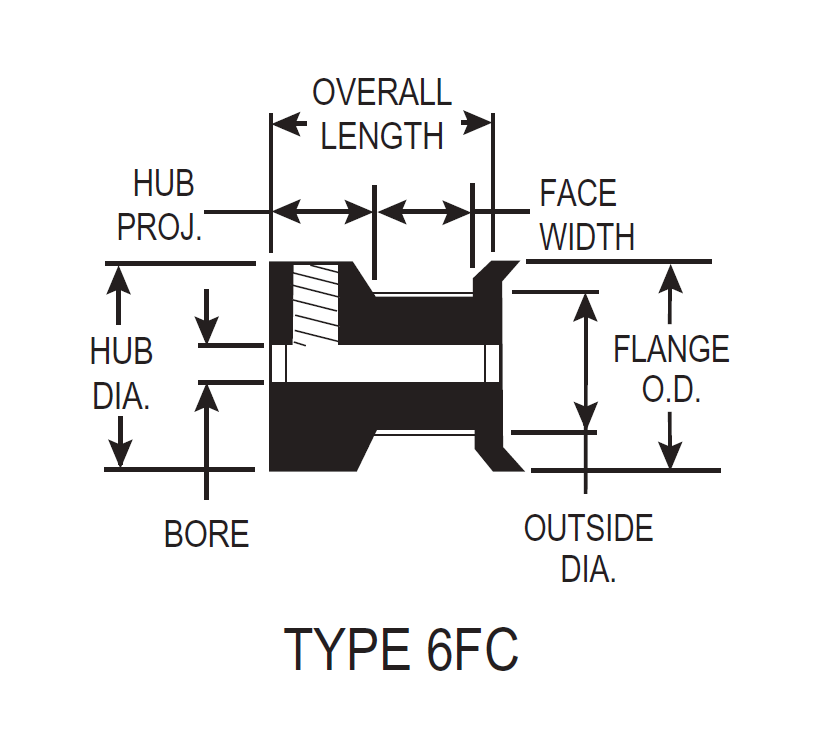

Type 6FC features a flange on one side. This design also includes a clearly defined hub projection and face width, which provides stable support for the timing belt while allowing for a tighter installation. |

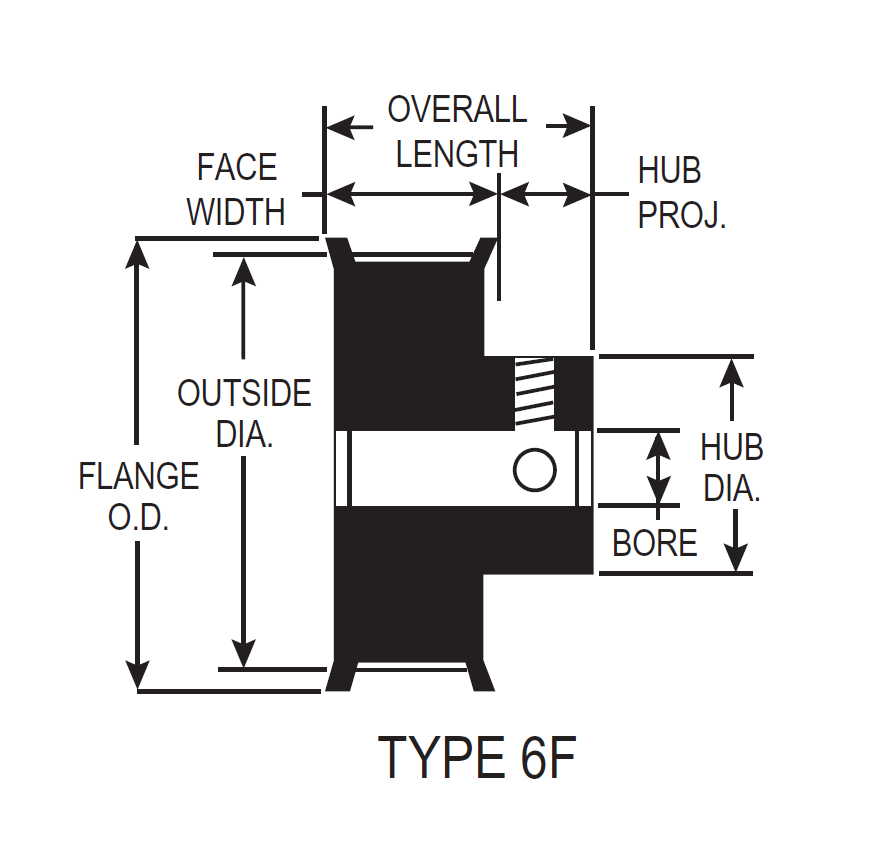

Type 6F - Long hub projection and wide face width makes it suitable for applications that require more stability and alignment. |

|

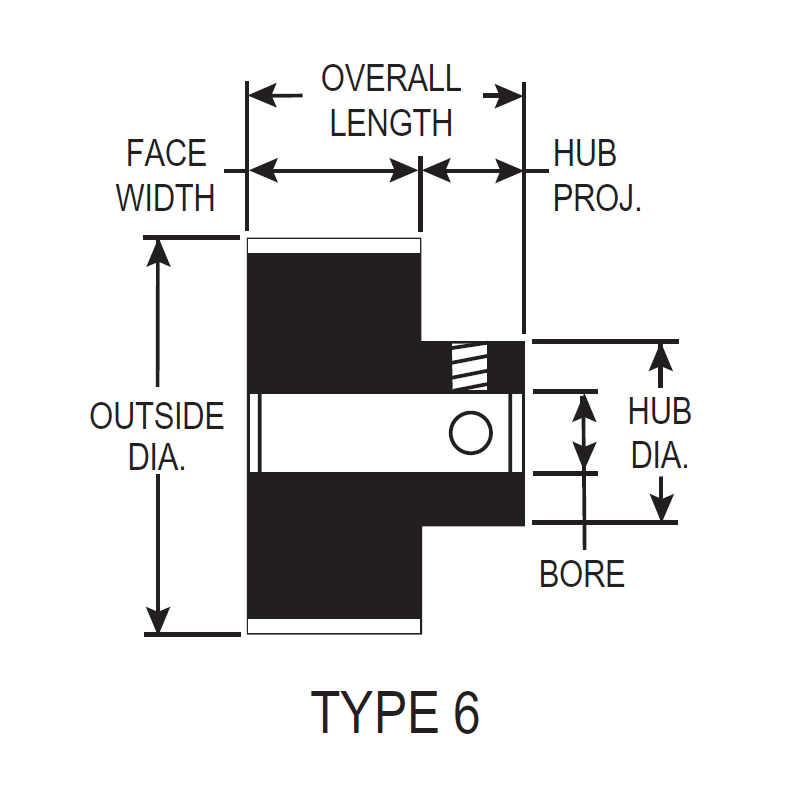

Type 6 - Similar to Type 6F but without flanges. This type has a simpler design with wider face width and shorter hub projection. Suitable for general timing belt applications. |

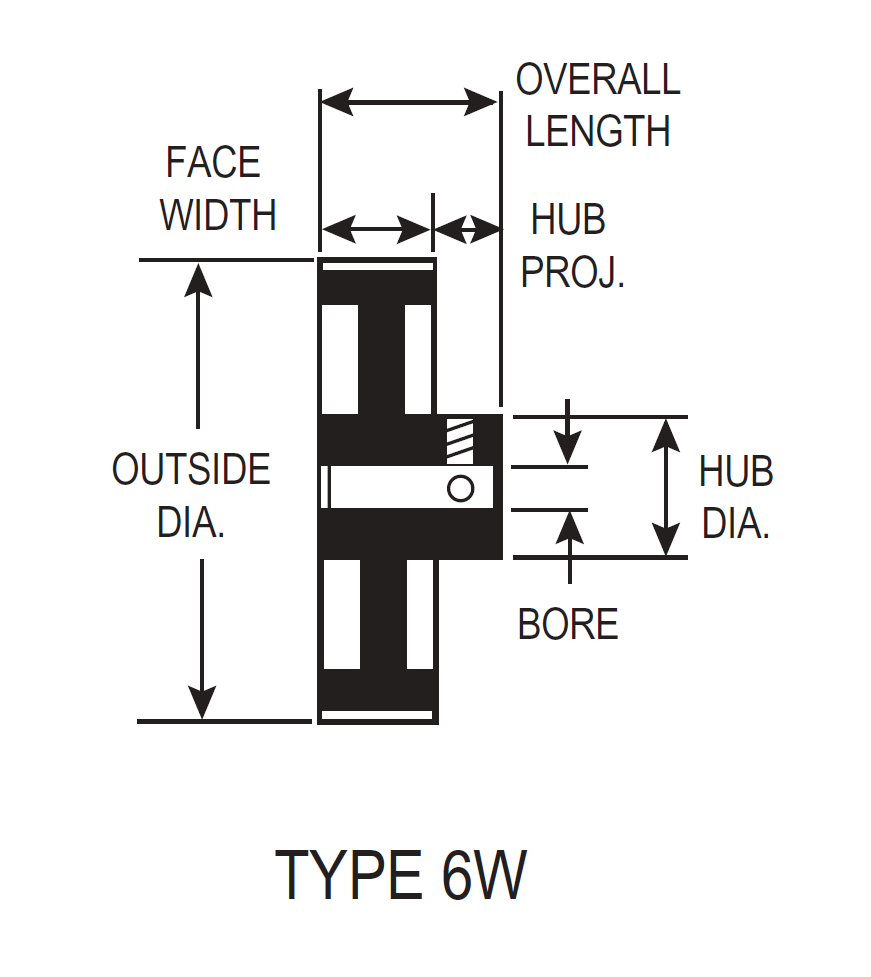

Type 6W - This is a lighter version of Type 6, often with cutouts or reduced material in the hub to reduce weight without compromising dimensions. Suitable for applications where weight reduction is important. |

|

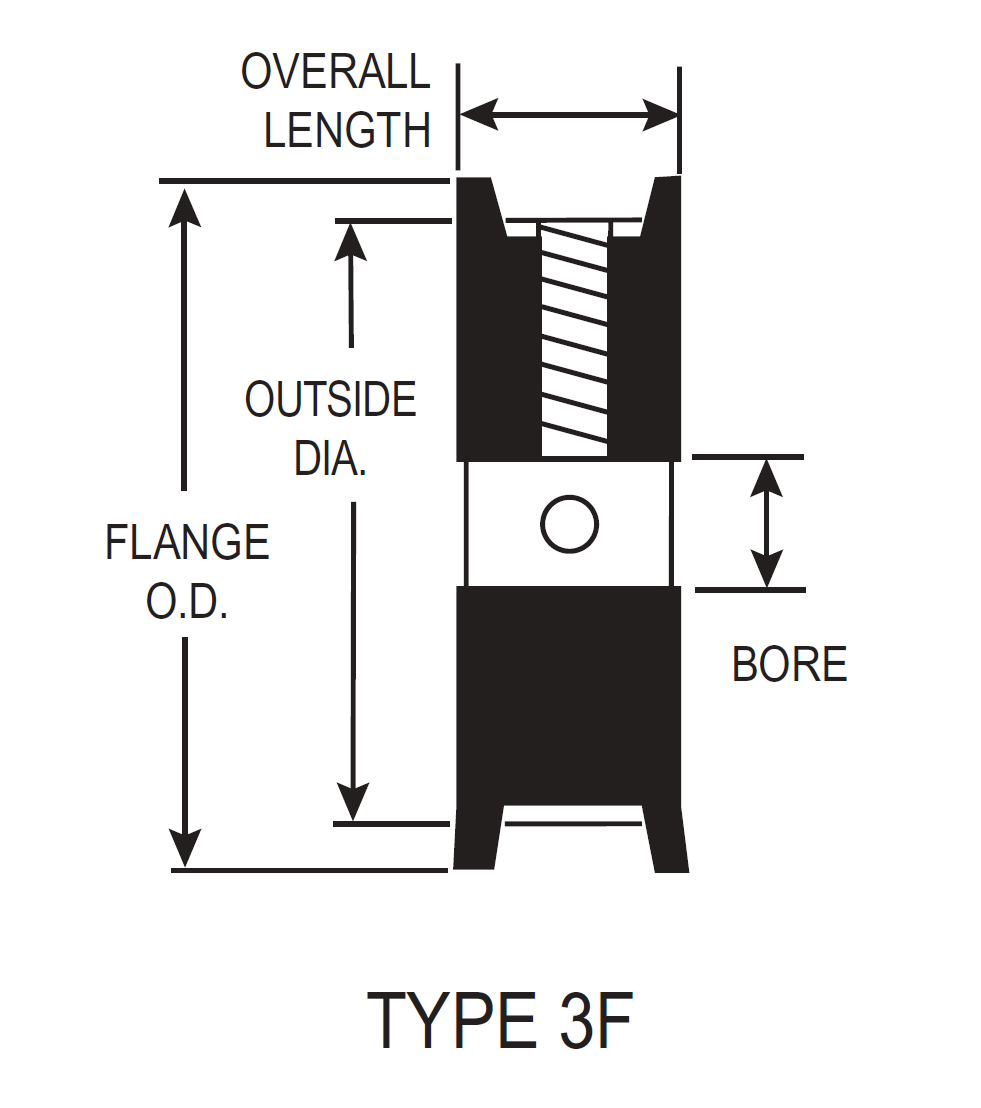

Type 3F has flanges on both sides, full containment of the belt. This type is ideal for applications where belt misalignment could cause big problems. |

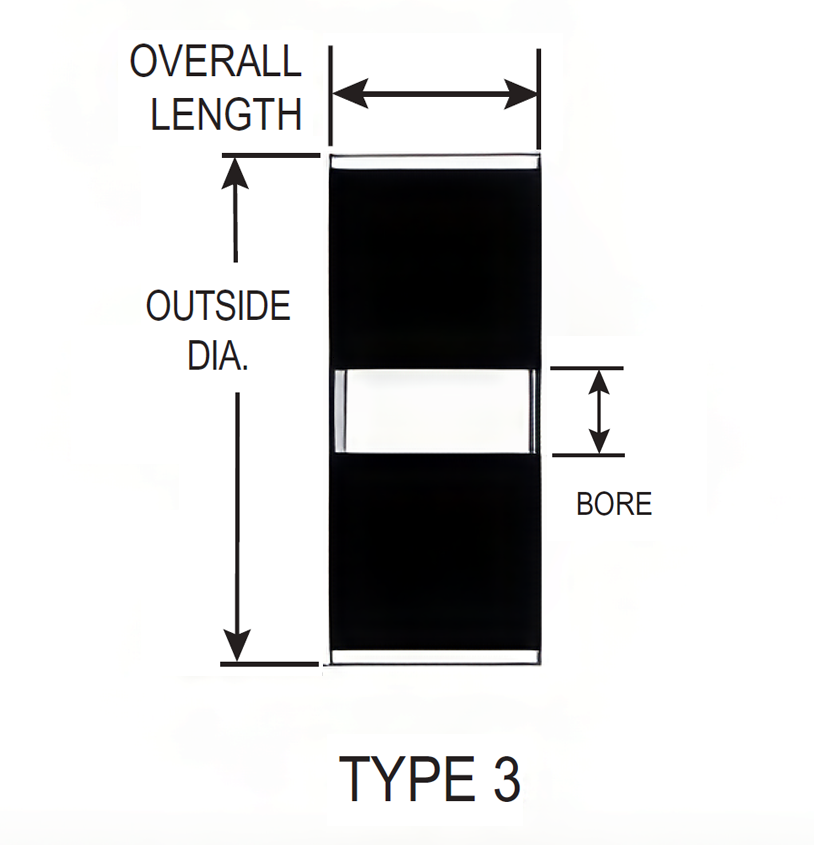

Type 3 is a simple, non-flanged timing pulley with a streamlined profile. This type has a straightforward cylindrical shape with no additional features like flanges or extended hub projections. |

We offer a wide selection of timing belt pulleys to meet diverse application requirements.

Each of these pulley types is for specific needs, whether it’s for added support, weight reduction or improved belt tracking. Let our team help you choose the right pulley type for your application for optimal performance and durability.

Varieties of Timing Belt Pulleys

-

Standard Timing Belt Pulleys: For general purpose applications, these pulleys provide consistent and synchronized movement. Available in various pitches: MXL, XL, L, H, T, AT series, suitable for many systems.

-

High Torque Timing Pulleys (HTD): For high torque applications, these pulleys have a deeper and rounded tooth profile to reduce belt slippage. Available in 3mm and 5mm pitches for metric and inch systems.

-

PowerGrip® Timing Pulleys: For reduced noise and longer life, these pulleys are used in precision applications. Often part of branded systems and available in aluminum or steel for high durability.

-

Custom Timing Pulleys: For specific applications or special requirements, custom pulleys can be made to any pitch, material or tooth profile. This customization ensures the perfect fit and performance for your system.

Timing Belt Pulley Installation and Maintenance

Installation and maintenance of timing pulleys is critical for optimal performance and life. Here’s what to consider:

-

Align Properly: Misalignment can cause premature wear and reduced performance. Make sure the pulley and timing belt are aligned during installation.

-

Use Right Tools and Techniques: Don’t use excessive force when installing the pulley, it can damage the pulley and the timing belt. Use the right tools to get a secure fit.

-

Consider Shaft-Saver for Extra Shaft Protection: Our Shaft-Saver solution prevents shaft damage by reducing friction between the shaft and pulley. By spreading the pressure more evenly and adding an extra layer of protection, Shaft-Saver minimizes wear and tear on the pulley and shaft, extending the life of your equipment.

-

Inspect Regularly: Inspect the pulley and timing belt for wear or damage. Replace any damaged parts immediately to prevent further issues.

-

Keep Clean: Keep the pulley and timing belt clean and debris free. Regular cleaning prevents corrosion (for steel pulleys) and wear.

-

Follow Manufacturer’s Guidelines: Follow the maintenance and replacement schedules recommended by the manufacturer to ensure the life and efficiency of your timing belt pulleys.

Alignment for Optimal Performance

Proper alignment is key to optimal timing belt pulley performance. Misalignment can cause reduced efficiency, increased wear and premature failure of both the pulley and the timing belt. To align properly follow:

-

Use Precision Alignment Tools: Use a laser alignment tool or other precision alignment method to align the pulley with the timing belt.

-

Check Position and Orientation: Make sure the pulley is seated and aligned with the shaft. This is critical for the system to work properly.

-

Check Belt Tension and Alignment: Make sure the timing belt is properly tensioned and aligned with the pulley. Incorrect tension can cause slippage and wear.

-

Adjust Alignment: Use shims or other adjustment method to fine tune the alignment as needed. With our Shaft-Saver you can reposition the pulley as needed. Small changes can make a big difference.

By aligning the pulley properly you can optimize your timing belt pulleys, reduce wear and tear and increase efficiency and reliability.

Tips for Efficiency

-

Match Belt and Pulley: Always match the belt pitch with the pulley pitch. This ensures a snug fit and no slippage for better energy efficiency and consistent performance.

-

Belt Tensioners: A properly tensioned timing belt prevents slippage which is key to system efficiency. Tensioners help you get the right tension regardless of load or system size.

-

Choose Lightweight Where Possible: If your application can use aluminum pulleys the weight reduction can give you big efficiency gains especially in high speed systems.

-

Custom Solutions: For non-standard applications consider getting custom timing pulleys that fit your needs. Customization can mean choosing the material, size or pitch that fits your requirements and will extend the life of the system.

Applications for High-Efficiency Timing Belt Pulleys

Robotics: Precision is key in robotics. Using the right pitch pulley means precise control of each joint and axis.

Medical: Reliable motion is critical in medical devices. The efficiency of a well-matched timing pulley system means better and safer operation.

Industrial Automation: Timing pulleys are key in automation systems, providing the synchronization for packaging and sorting without energy loss. Our timing belt pulleys come in various sizes and types to fit your automation needs.

Aerospace: Aerospace applications demand high precision and reliability. Timing pulleys are used in various systems to ensure accurate and efficient operation under extreme conditions.

Manufacturing: In manufacturing, timing belt pulleys are used in conveyors and machinery to maintain consistent and synchronized operations, improving productivity and reducing downtime.

Overall, timing belt pulleys are indispensable in any application where synchronized movement and power transmission are critical, making them a key component in both everyday devices and specialized industrial equipment.

Conclusion

Selecting the right timing belt pulley is key to increasing efficiency and performance in power transmission. Check out our products and find the one that fits your needs. Consider pitch, material and application. Match the belt and pulley, choose the right material and tension.

Consult a expert if needed to optimize your system with the right pulley.