Stock

Products

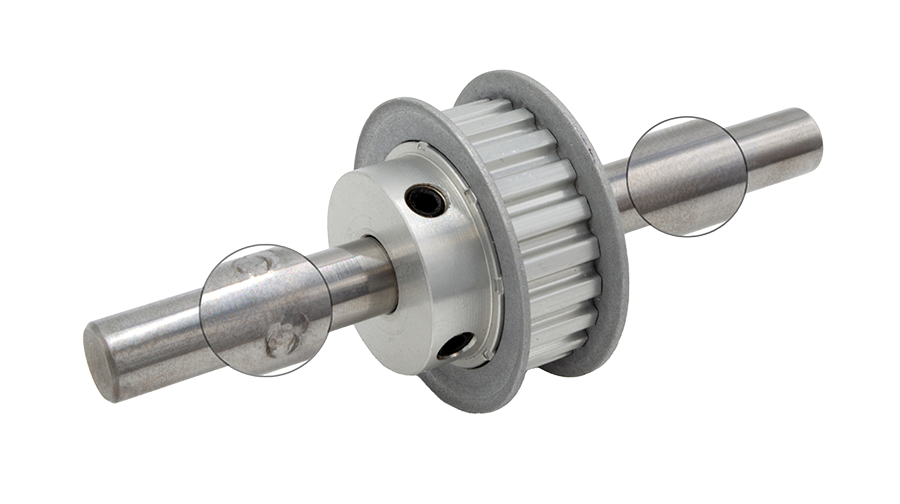

Timing

Belt Pulleys

At York Industries, we take great pride in our stock timing belt pulleys, a coveted product that has garnered widespread acclaim. With our state-of-the-art manufacturing capabilities, we produce an impressive volume of these exceptional pulleys annually, serving customers across the globe. Renowned for their superior quality, our pulleys play a vital role in synchronous drives and power systems, finding applications in diverse industries ranging from medical and robotics to sorting and packaging.

Set Screw Hub:

A higher-performance tooth design for applications where accuracy is critical, such as computer printers and storage equipment, robotics and medical diagnostic equipment.

- 2mm GT2 Pitch

(Inch) - 3mm GT2 Pitch

(Inch) - 3mm HTD Pitch

(Inch) - 5mm HTD Pitch

(Inch) - 080'' MXL Pitch

(Inch) - 0816'' (40 DP) Pitch

(Inch) - 1/5 XL Pitch

(Inch) - 3/8 L Pitch

(Inch)

Shaft-Saver™ Hub:

Our timing belt pulleys come with York Shaft-Saver™ hub option which prevent the usual shaft damage caused by set screws, allowing easy replacement or re-adjustment of timing pulleys in the field.

Timing

Pulley Stock

York Industries offers precision timing pulley stock, ready for your customization. Transform our semi-prepared pulley into a high-performance timing belt pulley of your own design. Choose the length, tooth profile, grooves, and material to suit your application. While our standard timing pulley stock is manufactured from durable aluminum, we offer custom quotations for alternative materials like steel.

York Industries offers timing pulley stock available in eight different pitch variants:

Timing

Pulley Flanges

Pulley flanges manufactured by York Industries are important components that help to secure the side guide of the timing pulley. With pulley flanges offered by York, you can be certain the timing belt in your synchronous drive will not slip from the pulley. When you choose pulley flanges from York Industries, you can expect top-notch performance and reliability. We understand the importance of precise and dependable components in your engineering projects, which is why we offer a wide range of timing pulley flanges in our online shop.

York Industries offers timing pulley flanges available in eight different pitch sizes:

- 2mm GT2 Pitch

(Inch) - 3mm GT2 Pitch

(Inch) - 3mm HTD Pitch

(Inch) - 5mm HTD Pitch

(Inch) - 080'' MXL Pitch

(Inch) - 0816'' (40 DP) Pitch

(Inch) - 1/5 XL Pitch

(Inch) - 3/8 L Pitch

(Inch)

To facilitate your design process, we provide free downloads of CAD models and PDF files for each timing belt pulley flange available in our online shop. This allows you to easily incorporate our flanges into your design and ensure a perfect fit.

Timing

Belts

With decades of experience, York Industries has been a trusted provider of precision timing belts. Our toothed belts work smoothly with any type of timing belt pulleys and flanges. To meet the diverse requirements of our customers, York offers customized solutions by cutting the timing belts to a precise width and length specifications. In line with our commitment to customer satisfaction, we provide convenient access to our extensive collection of timing belts through our online shop. Each timing belt is accompanied by a complimentary CAD model or downloadable PDF file, allowing engineers to easily integrate our products into their designs.

York Industries offers timing belts available in eight different pitch types:

PowerGrip GT2 AND GT3:

PowerGrip GT2 AND GT3 provide a higher-performance tooth design for applications where accuracy is critical, such as computer printers and storage equipment, robotics, and medical diagnostic equipment. Read more about PowerGrip GT2 and GT3 belts in our engineering knowledge center.

TRUMOTION TIMING BELTS:

Trumotion timing belts are precision non-marking, ultra clean belts available in 2 mm GT, 3 mm GT, 3 mm HTD, 5 mm HTD, .080”, 1/5”, and 3/8” tooth profiles for use where cleanliness is critical. Made to order. Read more about Trumotion belts in our engineering knowledge center.

You can also use our Center Distance Calculator to find the exact timing belt you are looking for in just a few seconds!

Timing

Belt Tensioners

York Industries introduces a comprehensive selection of precision-engineered tensioners, essential components employed in synchronous power drives to mitigate belt cogging and slipping, while significantly enhancing belt longevity. With effortless adaptability to varying drive tolerances, our tensioners facilitate precise center distance attainment using standard stock timing belt lengths, simplifying installation and field servicing, even in fractional horsepower systems.

Meticulously manufactured with utmost precision, our tensioners seamlessly integrate with various types of small synchronous drives, owing to their innovative slot and pivot designs. Our comprehensive tensioner range encompasses four distinctive types, each available in two size variations:

York's static tensioners are renowned for their exceptional functionality, ideally suited for power drives with minimal irregular force transmission, where belt stretching and wear are inherently limited. Conversely, dynamic tensioners find extensive application in synchronous drives, adeptly compensating for belt wear through self-adjustment capabilities. These tensioners exhibit superior tolerance for minor installation errors and inaccuracies, simplifying adjustment and replacement procedures.

Flexible

Flexible- • Universal - works with any small drive

- • Slot and pivot designs available

- • Extremely low belt clearance

Convenient

Convenient- • Drops right into your design

- • Small footprint

- • CAD drawings already available

- • Stock mounting spacers if needed in your design

- • Ready to ship in 48 hours

Cost Effective

Cost Effective- • Standard catalog item

- • Save cost of designing your own

- • Save tooling costs

CONFIGURE YOUR OWN TENSIONER

Why spend time designing, researching components, and specifying tensioning devices when you can do it all in seconds at www.york-ind.com? Using our exclusive online tool you can configure any of our universal tensioners to fit your design perfectly, download CAD drawings, and even request a free quote. The line includes four styles of tensioners in two sizes each. They offer small footprints and extremely low belt clearance. York's easy-to-use, menu-driven configuration tool walks you through the process of designing a custom tensioner for your drive.

Dynamic Pivot Type

Size 3 Engineering Data

Operating Characteristics

- Tensioner stroke - .73 inches (18.5mm)

- Range of adjustment - 1.20 inches (30.5 mm) over a 75 degree arc

- Maximum force against belt - 2.5 pounds (1.1 kg) continuos, 10 pounds (4.5 kg) peak

Size 4 Engineering Data

Operating Characteristics

- Tensioner stroke - .50 inches (12.7 mm) over a 75 degree arc

- Range of adjustment - 1.12 inches (28.4 mm)

- Maximum force against belt - 5 pounds (2.3 kg) continuos, 15 pounds (6.8 kg) peak, 10 pounds (3.6 kg) continuos available

Dynamic Slot Type

Size 3 Engineering Data

Operating Characteristics

- Tensioner stroke - .25 inches (6.4 mm)

- Range of adjustment - .50 inches (12.7 mm)

- Maximum force against belt - 2.5 pounds (1.1 kg) continuos, 10 pounds (4.5 kg) peak

Size 4 Engineering Data

Operating Characteristics

- Tensioner stroke - .25 inches (6.4 mm)

- Range of adjustment - .80 inches (20 mm)

- Maximum force against belt - 5 pounds (2.3 kg) continuous, 15 pounds (6.8 kg) peak

- Spring can be mounted to push on idler (as shown) or to pull

Static Pivot Type

Size 3 Engineering Data

Operating Characteristics

- Range of adjustment - .73 inches (18.5 mm) over a 44º arc

- Maximum force against belt - 8 pounds (3.6 kg) continuous, 10 pounds (4.5 kg) peak

Size 4 Engineering Data

Operating Characteristics

- Range of adjustment - 1.25 inches (31.8mm) over a 44º arc

- Maximum force against belt - 10 pounds (4.5 kg) continuous, 15 pounds (6.8 kg) peak

Static Slot Type

Size 3 Engineering Data

Operating Characteristics

- Range of adjustment - .50 inches (12.7 mm)

- Maximum force against belt - 2.5 pounds (1.1 kg) continuos, 10 pounds (4.5 kg) peak

Size 4 Engineering Data

Operating Characteristics

- Range of adjustment - .80 inches (20mm)

- Maximum force against belt - 10 pounds (4.5 kg) continuous, 15 pounds (6.8 kg) peak