Revolutionize Your Drive System with Shaft-Saver™ Timing Belt Pulleys from York Industries

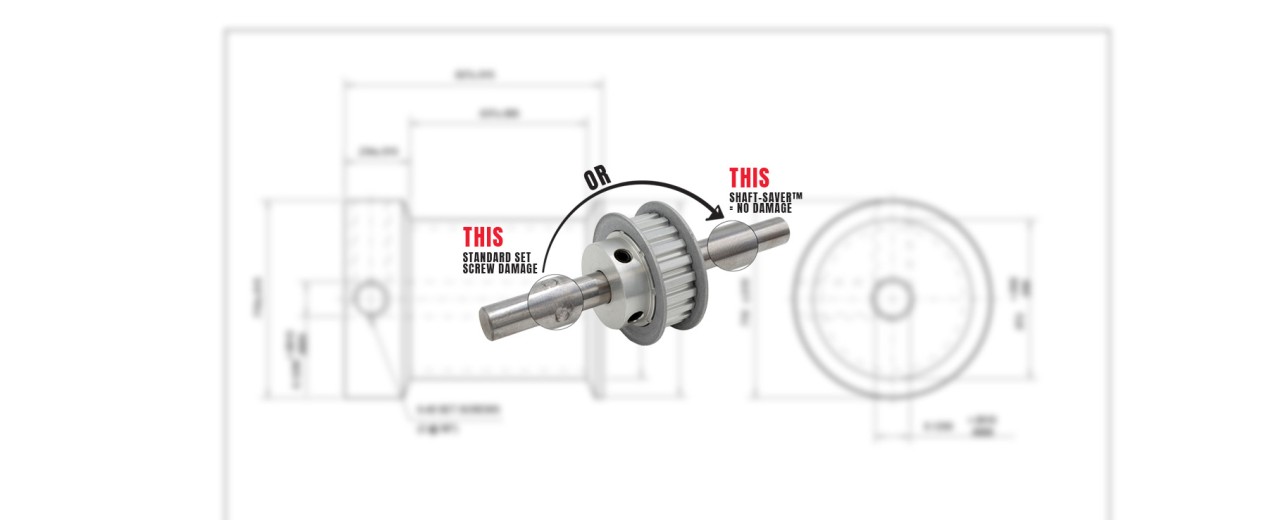

In the world of drive systems, the reliability and maintenance of your components are crucial for long-term efficiency and cost-effectiveness. York Industries’ Shaft-Saver™ Timing Belt Pulleys offer an innovative solution to one of the most persistent issues in drive systems—shaft damage caused by traditional set screws.

The Problem with Standard Set Screws

Standard cup point set screws, the industry norm for securing timing pulleys to shafts, have long been known to cause shaft deformation. When these screws are tightened, they create a crater-like indentation in the shaft. This not only complicates the removal or adjustment of the pulley but also makes precision alignment difficult, often requiring additional machining or the use of costly alternative hubs.

Enter the Shaft-Saver™: Precision without Compromise

York Industries’ Shaft-Saver™ addresses these challenges head-on. Utilizing a special copper alloy tip, the Shaft-Saver™ set screw conforms perfectly to the shaft, eliminating the risk of shaft damage while maintaining a firm grip. The innovative design allows for:

- Easy and Precise Adjustments: Unlike traditional set screws, the Shaft-Saver™ does not create a dent in the shaft, making subsequent adjustments straightforward and hassle-free.

- No Shaft Damage: The copper alloy tip deforms slightly to provide a perfect fit without marking or damaging the shaft.

- Uncompromised Holding Power: Despite the softer tip, the Shaft-Saver™ delivers holding power equal to or greater than that of a standard set screw, ensuring reliable performance under even the most demanding conditions.

| TIMING PULLEY FASTENER SELECTION GUIDE | |||||||

|---|---|---|---|---|---|---|---|

| Fastening Method | A | B | C | D | E | F | G |

| York Shaft-Saver™ | Y | Y | Y | Y | Y | Y | Y |

| Modified Hubs (Offset screws) | Y | Y | n | n | Y | n | n |

| Clamps (Separate Components) | Y | n | n | n | n | Y | Y |

| Keys | n | n | n | n | n | Y | Y |

| Pins | n | n | n | Y | Y | Y | Y |

| Cup Point Setscrews | n | n | n | Y | Y | Y | Y |

Fastening Flexibility: The Shaft-Saver™ Advantage

The versatility of Shaft-Saver™ is evident when compared to other fastening methods. It outperforms traditional options in nearly every category, as detailed in the Timing Belt Pulley Fastener Selection Guide:

A: Shaft remains smooth and unmarked.

B: Self-contained solution—no additional components needed.

C: Part is fully supported on the drive axis with no offset.

D: Easy readjustment.

E: Pinning is possible if needed.

F: Resistant to dirt and debris.

G: Holding power is not overly sensitive to screw torque.

This guide demonstrates the comprehensive advantages of using Shaft-Saver™ over conventional methods, especially in applications where maintaining the integrity of the shaft is paramount.

Superior Performance: Shaft-Saver™ Gripping Torque Values

Performance testing shows that Shaft-Saver™ provides robust gripping torque comparable to traditional Allen set screws, but without the associated drawbacks of shaft damage. The Shaft-Saver™ Gripping Torque Values Table highlights the impressive performance across various shaft diameters and materials, reinforcing its suitability for a wide range of applications.

Shaft-Saver™ Gripping Torque Values

| Shaft Dia. | Material, steel | Screw size | Shaft/hub break-away torque (inch/lb) | |||

|---|---|---|---|---|---|---|

| Standard Allen Set Screw (1) | Shaft-Saver Set Screw (2) | |||||

| 1 scr. | 2 scr. | 1 scr. | 2 scr. | |||

| .156 | Hardened and ground | 4-40 | 4 | 3 | ||

| .187 | Hardened and ground | 6-32 | 12 | 10 | ||

| .250 | Hardened and ground | 8-32 | 20 | 45 | 20 | 40 |

| .312 | Hardened and ground | 8-32 | 32 | 42 | 30 | 52 |

| .375 | Hardened and ground | 10-32 | 48 | 62 | 44 | 65 |

| .250 | Drill rod | 8-32 | 25 | 45 | 32 | 40 |

| .250 | Cold rolled steel | 8-32 | 20 | 35 | 12 | 22 |

1) Shafts sustained indentation damage from standard Allen set screws

2) Shaft-Saver shaft break-away torque exceeds the point where belt slippage occurs

| Test Condition: Maximum recommended screw torque in an aluminum hub per SAE recommendation, steel screw, Aluminum 2024 T4 hub, no lubrication | Screw size | Torque inch/lb |

|---|---|---|

| 4-40 | 3 | |

| 6-32 | 6 | |

| 8-32 | 11 | |

| 10-32 | 20 |

Real-World Success: A Case Study

A U.S. Navy equipment manufacturer faced challenges with gear alignment in precision applications. Traditional methods, including drilled and pinned gears and cup point set screws, were inadequate, leading to excessive rework and alignment difficulties. However, after switching to Shaft-Saver™ set screws, the manufacturer saw a significant improvement. The absence of shaft damage and ease of realignment drastically reduced rework, leading to better product performance and longevity.

A Solution That Pays Off

With a modest cost premium, Shaft-Saver™ delivers significant long-term savings by reducing shaft damage, simplifying maintenance, and ensuring reliable performance. It is the ideal choice for any application where precision and durability are critical.

Do you have additional questions? Don't hesitate to contact us. Our engineering team is ready to provide expert advice and help you find the best solution for your application. Reach out today and discover how Shaft-Saver™ can transform your operations.